An electric actuator is a device that can bring about the movement of a load or a resultant action requiring force with the use of an electric motor. It is a mechanical device that is used to change a supply of electrical energy into kinetic energy that can be harnessed and used in various applications. Read More…

Del-Tron Precision, Inc. was founded in order to serve the needs of automated equipment manufacturers for innovative, high quality and reasonably priced anti-friction linear bearings and associated products such as valve actuators.

Utilized in a variety of applications and industries, the products designed and manufactured at Burr Engineering & Development include ball screw actuators and similar mechanisms.

At IAI America, we are dedicated to providing value and originality with any product that we provide to you. Our linear actuator model types include slider, folded-motor slider, rod, and single, double, or ball-bushing type guided rod actuators. Our staff members are committed to being available in order to bring you full customer satisfaction while delivering the products that will best suit...

Isotech provides a number of different linear actuator & lifting columns for various applications. These products can be customized to meet your specific load requirements and travel distances. You can trust the accuracy of these solutions and the experts at Isotech is always available to assist you with your needs. Feel free to contact them today to learn more information!

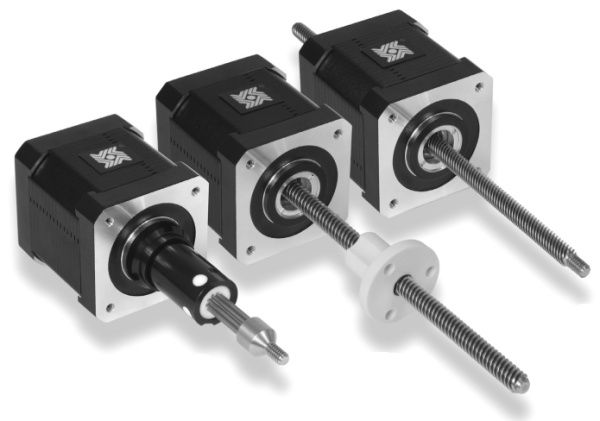

ElectroCraft hybrid stepper-based linear actuator solutions provide original equipment manufacturers the precision, performance and reliability that is required for a wide variety of motion control positioning applications. From medical and laboratory equipment to industrial machinery, ElectroCraft offers configurable or completely customizable solutions in three unique product designs: linear...

Our linear actuators are at the top of the market and on the leading edge of innovation. If you need a new design or modification to an existing design, we are the true professionals that you need to call.

Tusk Direct’s specialty is linear motion components. We offer slides, bearings, lubricants and assemblies compatible with pneumatic or electric actuators and actuator systems.

More Electric Actuator Manufacturers

How Electric Actuators Work

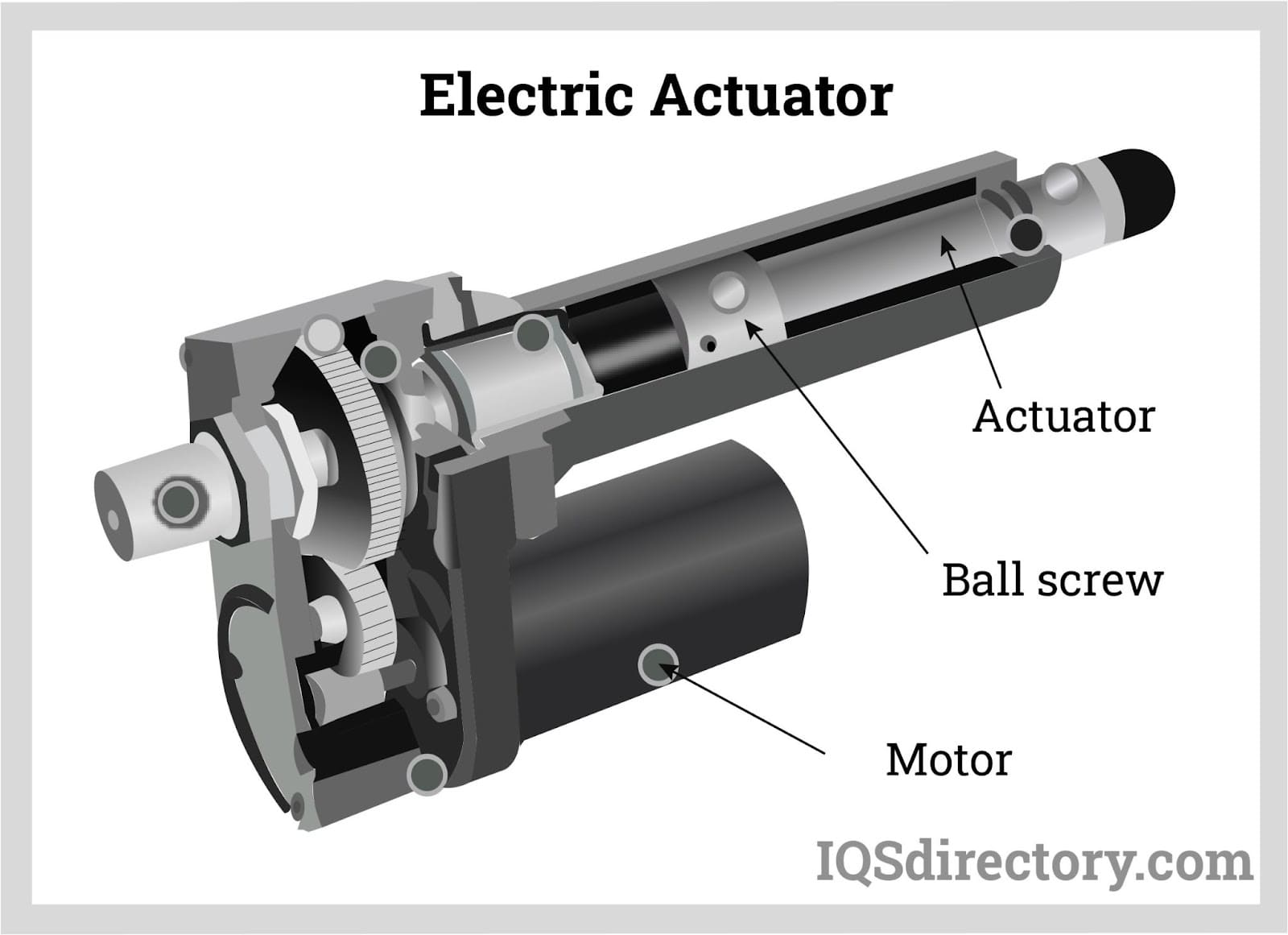

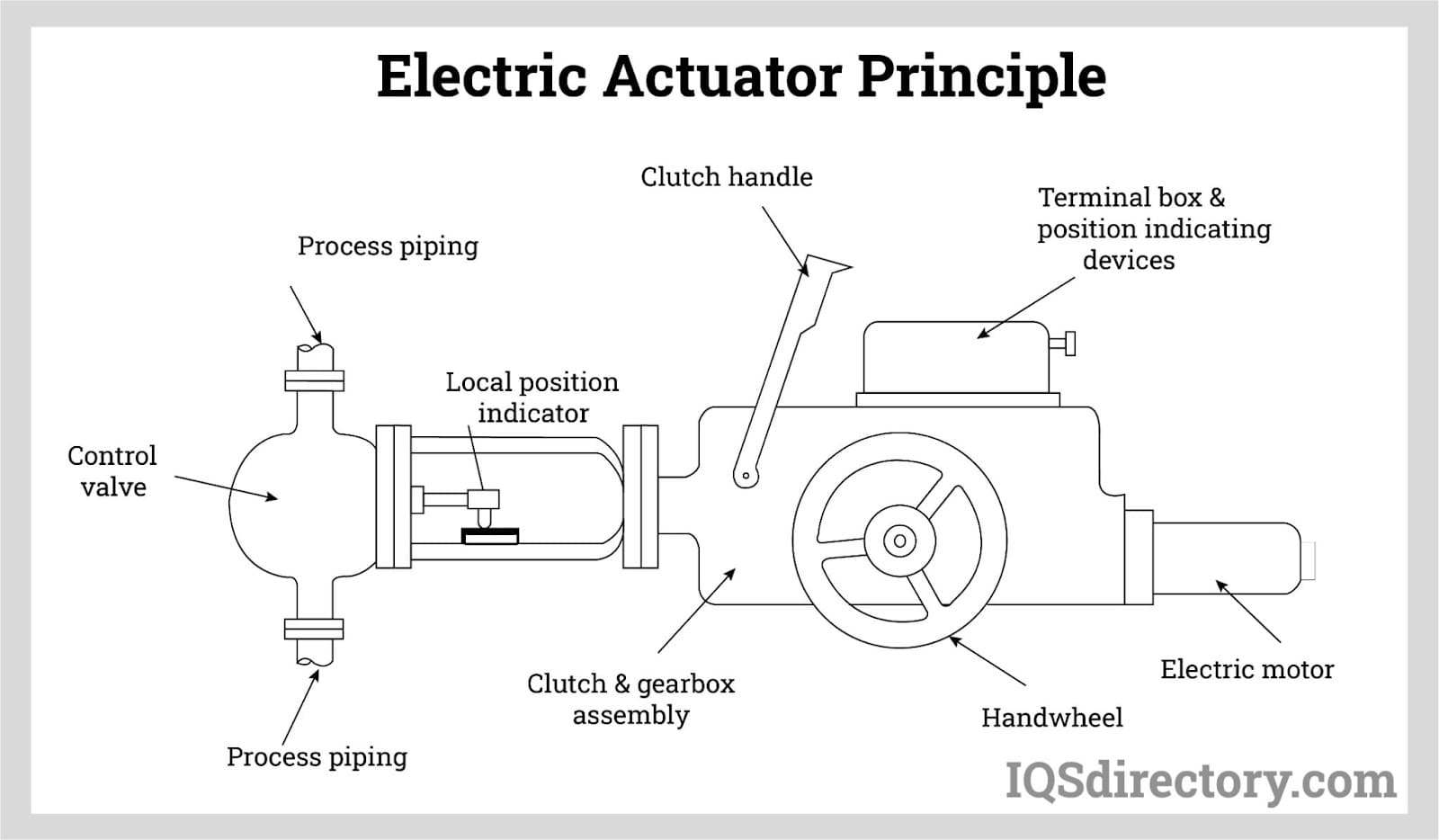

An electric motor can generate a rotary motion when its spindle or rotor rotates in a circular motion. The rotor is directly connected to the helical screw through a drive shaft, which provides a rotating force to the ball screw nut. The ball screw is moved either backward or forwards along the helical screw. Another hollow piston rod thereby creates linear motion. The rotation speed is varied by controlling the electric drive.

The power of the motor determines the overall torque. A communicating mechanism will provide the position information of the shaft and determine whether a stop or a change in direction is required. The linear electric actuator can be programmed and set to move in a specific direction until it reaches a certain position and then either stop or move on or maybe return to the rest position.

Considerations When Choosing an Electric Actuator

When deciding on whether to adopt the usage of an actuator, one needs to consider the type of force they require. For example, there are pneumatic linear actuators where the force is created by a pressure exerted on the surface area of the piston.

Electric actuators are an alternative when there is no supply of compressed air. When using electric actuators, the force is generated by the torque capability. A linear electric actuator is required when the system has multiple positions where a change in direction or force is required.

Types of Electric Actuators

Electric actuators can be divided into two main subcategories: rotary and linear.

Rotary Electric Actuators

Rotary actuators rotate from closed to open through the use of butterfly valves, plug valves, and a ball. The electromagnetic power from the electric motor makes the components rotate, allowing halts during each stroke. The rotary electric motors also provide an incremental rotating movement in the output shaft.

Its most basic form consists of a motor coupled with a speed reducer. They incorporate a wide range of additional components such as clutches, brakes, rotating gears, and seals.

Linear Electric Actuators

Their robust nature to shock loads affects the actuator's general lifespan, unlike ball screws which run smoothly without any friction and, therefore, have greater efficiency.

Applications and Benefits of Electric Actuators

The applications and benefits of electric actuators include:

Applications of Electric Actuators

Electrical actuators are made use of in a wide variety of industrial applications. For example, they are used in the food and beverages industry to manufacture PET bottles, labeling systems, filling components, and robotic milking machines. In addition, the automotive industry uses actuators in driverless motor vehicles.

Other applications are in dispensing and selecting jointing methods like welding and reverting. They are also used in agricultural equipment where they are fitted to powered hydraulics for more finessed movements. Cutting equipment also makes use of actuators in the lowering or precise movement of the cutting blades.

Advantages of Electric Actuators

Electric actuators are very accurate at controlling movement or the equipment's general position. They also do not require extensive maintenance as their setup is not complex.

Electric actuators also have dependable efficiency when used at very high speeds. Finally, the actuators come with very little operating cost since they use electrical energy and do not require numerous additives to function.

Choosing the Proper Electric Actuator Supplier

To ensure the most constructive outcome when purchasing electric actuators from an electric actuator supplier, it is important to compare several companies using our directory of electric actuator suppliers. Each electric actuator supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each electric actuator business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple electric actuator companies with the same form.

Air Cylinders

Air Cylinders Assembly Machinery

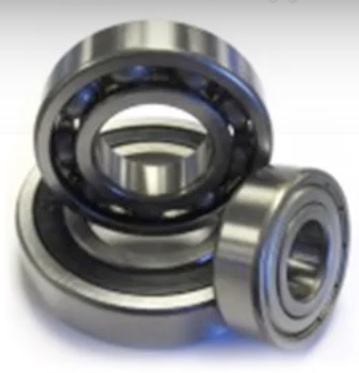

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services