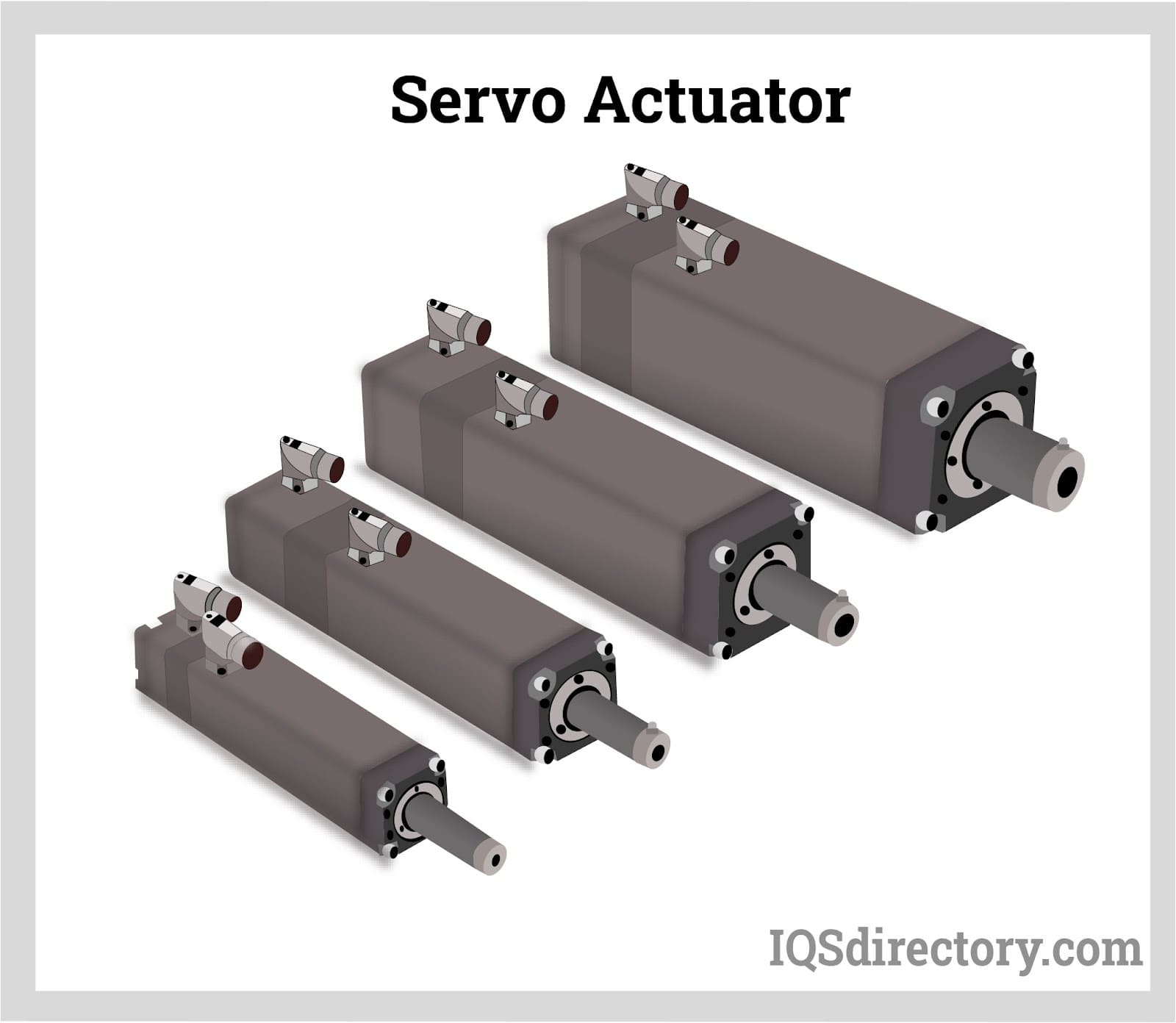

A servo actuator is a device used to rotate or push parts of a machine with precision. They allow for precise control of linear or angular position, acceleration, and velocity. These servo actuators can be powered through pneumatic, hydraulic, and electrochemical means. Read More…

Del-Tron Precision, Inc. was founded in order to serve the needs of automated equipment manufacturers for innovative, high quality and reasonably priced anti-friction linear bearings and associated products such as valve actuators.

Utilized in a variety of applications and industries, the products designed and manufactured at Burr Engineering & Development include ball screw actuators and similar mechanisms.

At IAI America, we are dedicated to providing value and originality with any product that we provide to you. Our linear actuator model types include slider, folded-motor slider, rod, and single, double, or ball-bushing type guided rod actuators. Our staff members are committed to being available in order to bring you full customer satisfaction while delivering the products that will best suit...

Isotech provides a number of different linear actuator & lifting columns for various applications. These products can be customized to meet your specific load requirements and travel distances. You can trust the accuracy of these solutions and the experts at Isotech is always available to assist you with your needs. Feel free to contact them today to learn more information!

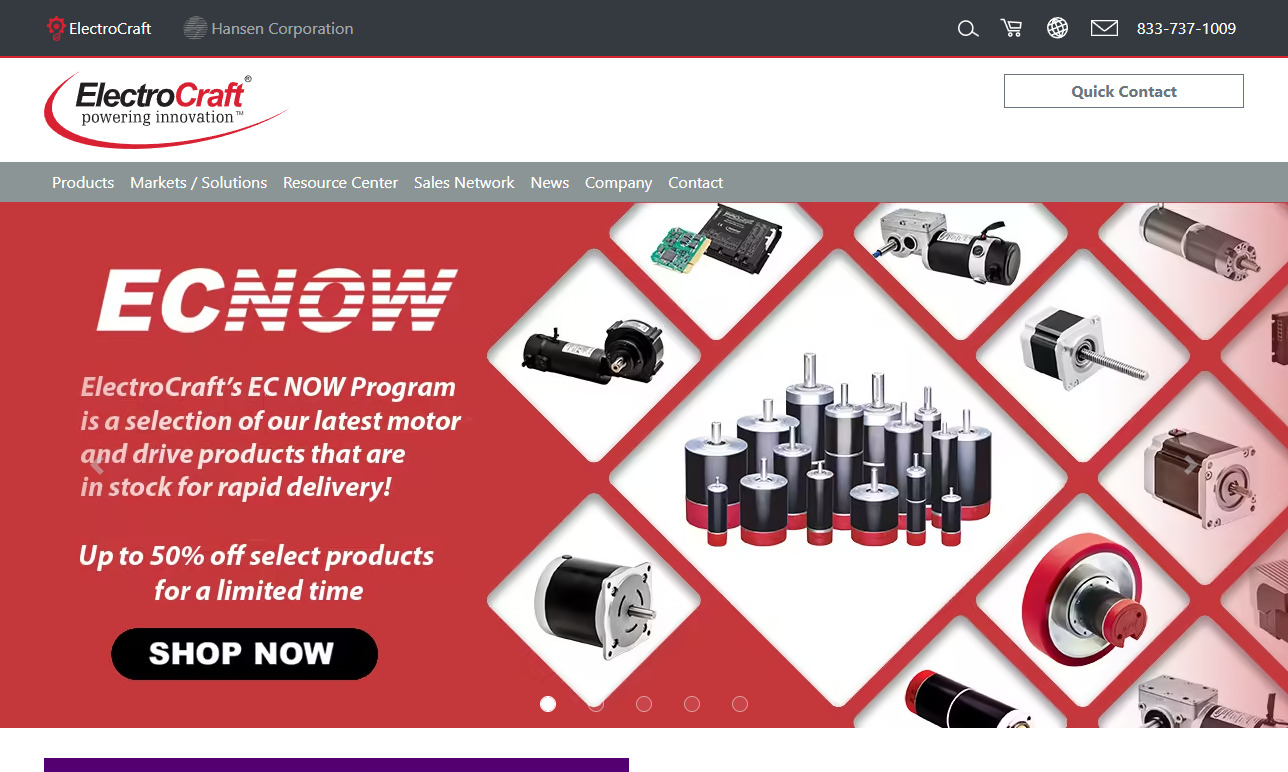

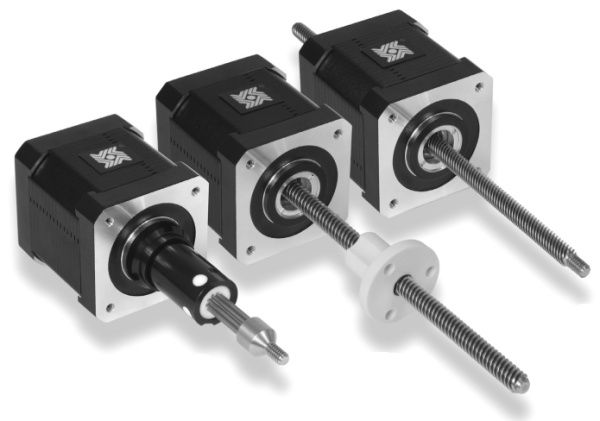

ElectroCraft hybrid stepper-based linear actuator solutions provide original equipment manufacturers the precision, performance and reliability that is required for a wide variety of motion control positioning applications. From medical and laboratory equipment to industrial machinery, ElectroCraft offers configurable or completely customizable solutions in three unique product designs: linear...

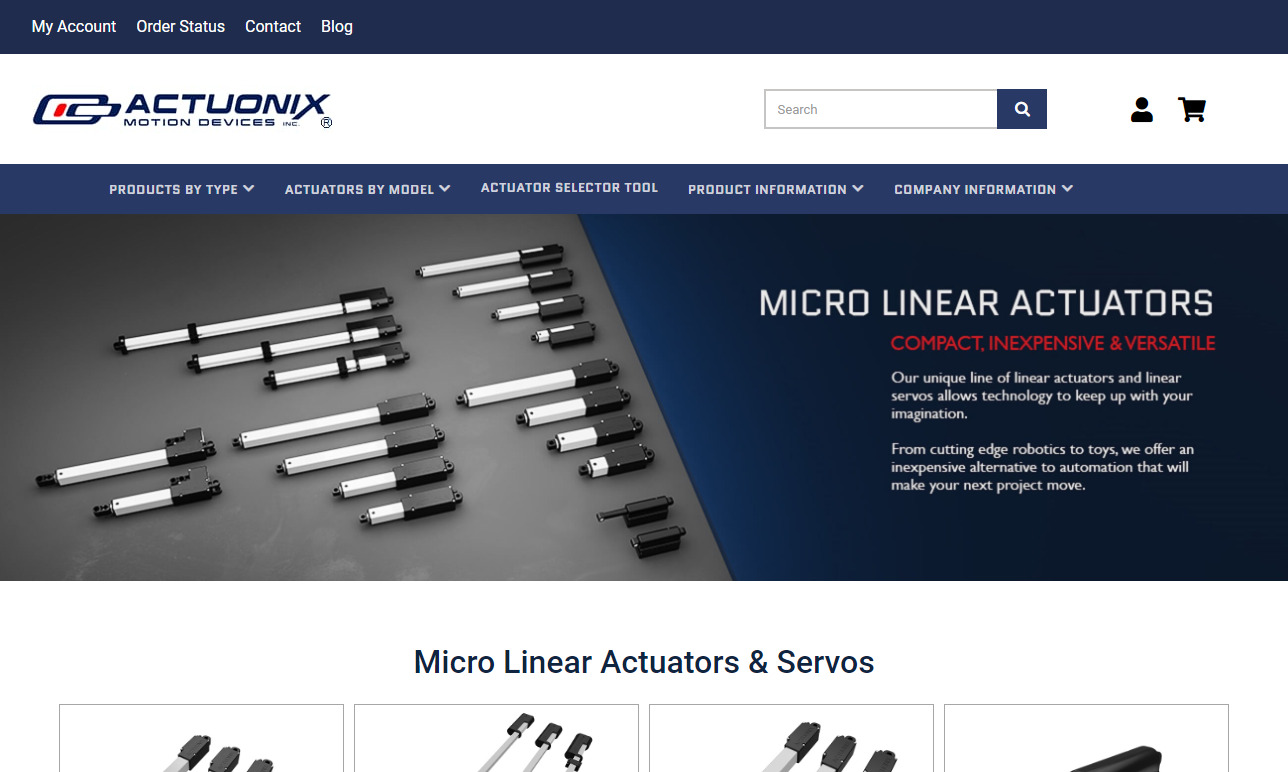

Our linear actuators are at the top of the market and on the leading edge of innovation. If you need a new design or modification to an existing design, we are the true professionals that you need to call.

Tusk Direct’s specialty is linear motion components. We offer slides, bearings, lubricants and assemblies compatible with pneumatic or electric actuators and actuator systems.

More Servo Actuator Manufacturers

What Is a Servo Actuator?

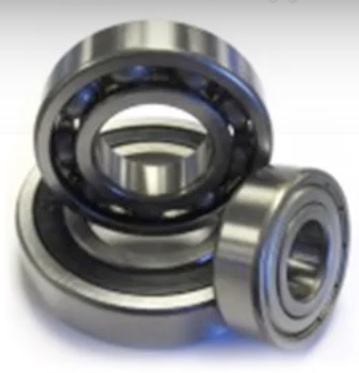

The choice of servo actuator depends on the speed, precision requirements, and power needed for the specific application. Servo actuators are composed of three main components: a set of gears, a servo motor, and an output bearing.

A suitable motor is coupled to a sensor for position feedback. In the servo actuator, a relatively sophisticated controller is also required. It is often a delicate module designed for specific use with servo motors.

How Servo Actuators Function

The servo actuators system consists of three basic components: an output sensor, a controlled device, and a feedback system. This system is an automatic closed-loop control system that provides torque and velocity as commanded by a servo controller, which uses a feedback device to close the loop.

In this setup, in place of controlling a device by applying a variable input signal, the contained device is controlled by a feedback signal generated by comparing the output signal and the reference input signal.

When the command signal or the reference signal is placed into the system, it is then compared to the output reference signal, which is contained by the system using the output sensor, and also a third signal produced by the feedback system. The third signal, produced by the feedback system, acts as an input signal for the controlled device.

The input signal to the device is present as long as there is a logical difference between the reference input signal and the output reference signal. The third signal, produced from comparing the two above signals, cannot and will not remain enough to operate the device further. And also, this signal will not be compatible with the production of further output for the system until the next reference input signal is introduced to the system.

This reference input signal can also be denoted as the command signal. Therefore, a servomechanism's primary mission is to maintain a system's output at the desired value.

Types of Servo Actuators

Servo actuators are found in many different sizes depending on the required function. Some types include continuous rotation, positional rotation, and the linear servo motor.

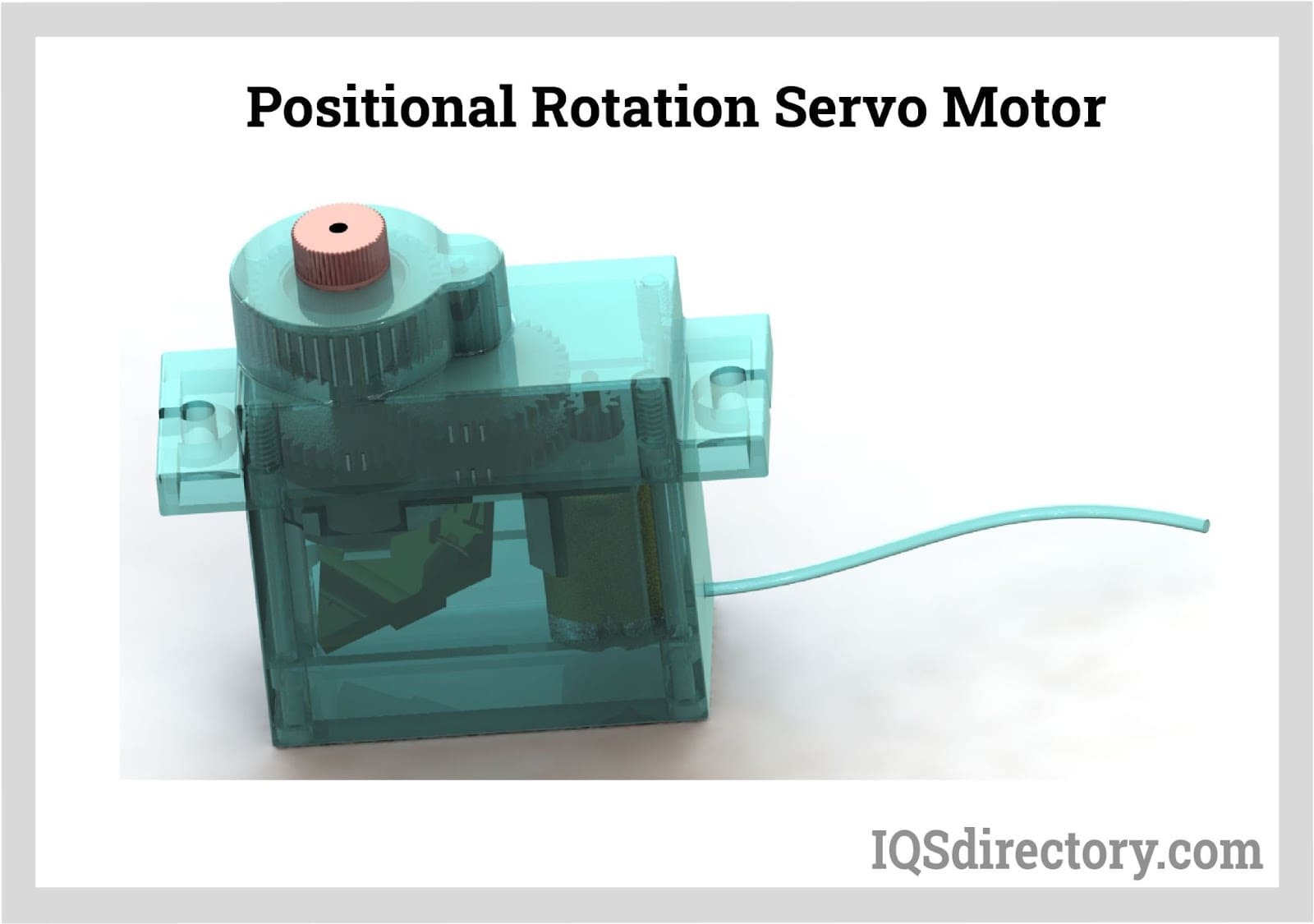

Positional Rotation Servo Motor

This type of servo can rotate 180 degrees. The positional rotation servo contains stops in their gearbox, and this helps in protecting the output shaft from over-rotating.

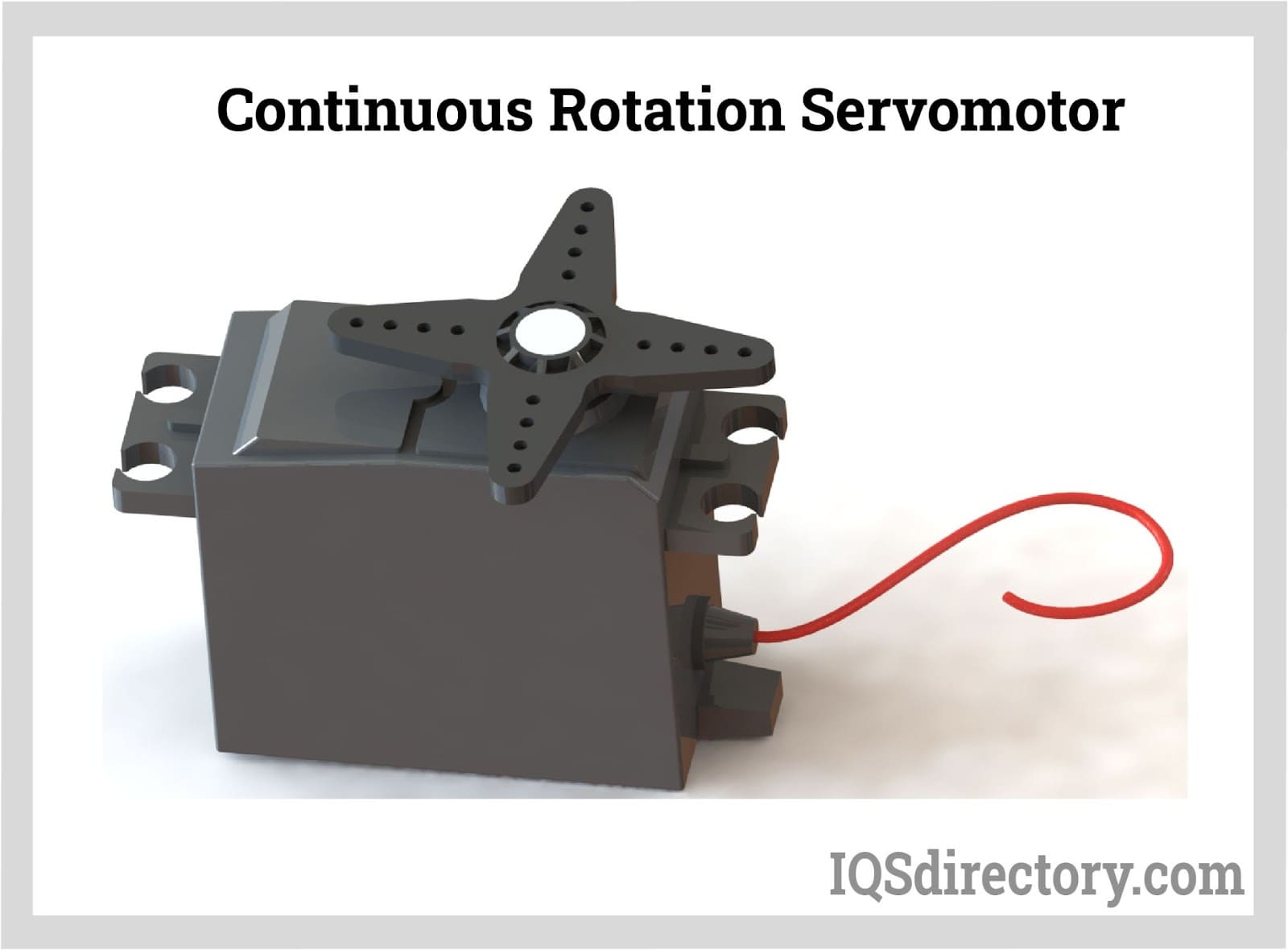

Continuous Rotation Servo Motor

This servo has a range of motion that is not limited. It does not use the input signal to determine which direction or position the servo should be able to turn. The continuous rotation of the servo relates the input to the speed of the output and the direction. The continuous rotation servo motor can move in both CW and CCW directions, which is possible due to their limitless movement.

Linear Servo Motor

This type of servo uses a rack and pinion mechanism to change their contained performance. This rack and pinion converts rotary motion into linear motion.

Applications and Uses of Servo Motors

Servo actuators are used in a wide range of applications, including in toys, home electronics, airplanes, and automobiles. The moving of levers back and forth to control the steering in drones or adjust the surfaces of the wings are some of the uses of servo actuators. Servos are used in automobiles to manage the speed of the vehicle. A servo motor can also regulate the car's speed, and in aircraft, it does so by rotating a shaft connected to the engine's throttle.

Choosing the Correct Servo Actuator Supplier

To ensure you have the most positive outcome when purchasing servo actuators from a servo actuator supplier, it is important to contact several companies using our directory of servo actuator suppliers. Each servo actuator supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each servo actuator business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple servo actuator companies with the same form.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services